Metal roofing has emerged as a viable alternative to traditional roofing materials, garnering a reputation for its durability, energy efficiency, and aesthetic appeal. Unlike conventional shingles or tiles, metal roofs are constructed from various metals, such as steel, aluminum, and copper, which contribute to their long-lasting nature and ability to withstand harsh weather conditions. This inherent resilience often results in a lifespan of 40 to 70 years, significantly surpassing standard roofing solutions.

One notable advantage of metal roofing is its energy efficiency. Metal roofs can reflect solar radiant heat, reducing cooling costs in warmer months and leading to substantial savings over time. Additionally, many metal roof systems are designed to accommodate insulation, further enhancing this energy-saving potential. This attribute not only benefits the homeowner but also contributes positively to the environment, aligning with modern sustainability goals.

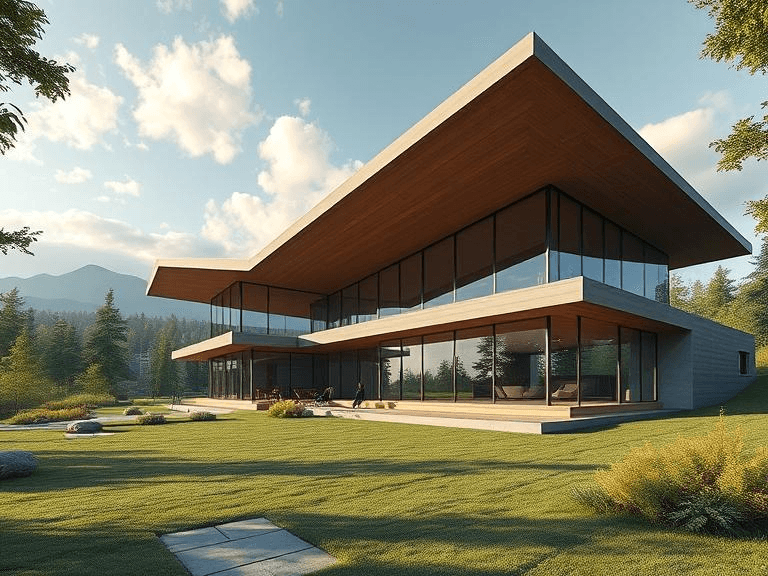

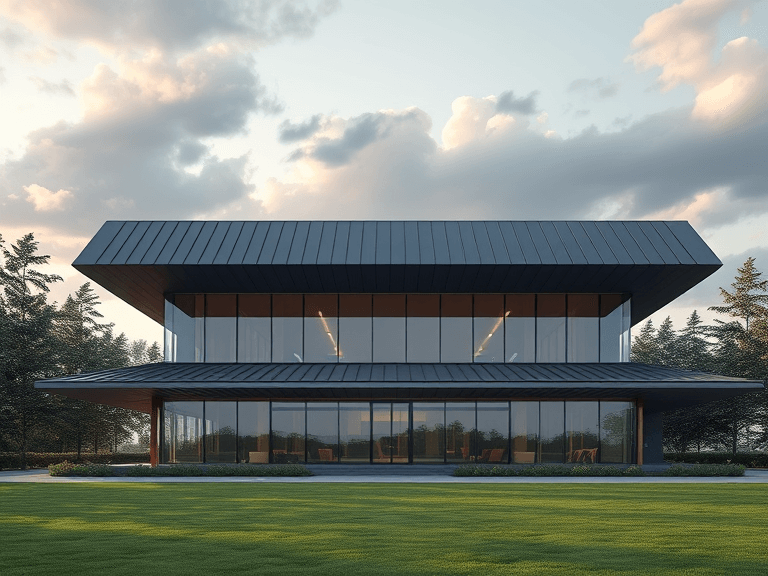

Aesthetic versatility is another compelling reason why homeowners are increasingly considering metal roofing for their residences. Available in a variety of styles, colors, and finishes, metal roofing can mimic traditional shingles or provide a more contemporary look depending on the homeowner’s preferences. This adaptability allows individuals to match their roof’s appearance with the overall design of their homes, thereby improving curb appeal and, potentially, property value.

There are several common types of metal roofing systems on the market today. Standing seam, corrugated metal, and metal shingles are among the popular choices that cater to various architectural trends and preferences. Each type brings its unique benefits and considerations, making it crucial for homeowners to assess their specific needs before opting for a metal roofing installation. Understanding these options is essential in making an informed decision that best suits one’s housing requirements.

Planning and Preparation

When embarking on a metal roofing installation, thorough planning and preparation are paramount to ensure a successful outcome. The first step in this process is to assess the current roof structure. This evaluation involves inspecting the integrity of the underlying materials and ensuring that they can support the weight of the metal roofing. It’s advisable to look for any signs of damage, such as rotting wood or rusted areas, which may necessitate repairs before installation can proceed.

Next, obtaining the necessary permits is crucial. Most local jurisdictions require permits for roofing projects, and failing to secure them can lead to fines or complications during the installation process. It is essential to check local building codes and regulations to determine what permits are needed for your specific project. Engaging with local authorities not only ensures compliance but also allows for a consultation on any specific guidelines relevant to metal roofing installation.

Proper measurements are another vital aspect of the planning phase. Accurate measurements will help in the procurement of the correct amount of materials, reducing waste and minimizing costs. It is advisable to measure the roof length, width, and slope accurately, accounting for any unique architectural features. Furthermore, creating a detailed material list is beneficial. Essential tools to have on hand before starting include a measuring tape, a level, safety goggles, an impact driver, and metal snips.

Additionally, ensuring the workspace is well-organized contributes significantly to the efficiency and safety of the installation process. Gather all required materials, such as metal panels, fasteners, and sealants, before beginning. By thoroughly preparing and planning, you can streamline your metal roofing installation, allowing you to focus on the task at hand while ensuring everything is in order. This foundational work is critical for minimizing errors and achieving the desired final outcome.

Choosing the Right Metal Roofing Material

When considering the installation of a metal roof, one of the most critical aspects is selecting the appropriate roofing material. There are several options available, each presenting its own set of benefits and drawbacks. The most commonly used materials for metal roofing include steel, aluminum, copper, and zinc.

Steel is often the most affordable choice among metal roofing materials. It is exceptionally durable and can withstand harsh weather conditions, making it an excellent option for a variety of climates. However, it is susceptible to rust if not properly coated or maintained, which can be a significant drawback for those in humid or coastal regions. Alternatively, aluminum is lightweight and resistant to corrosion, making it ideal for areas prone to moisture. Though aluminum roofs can be more costly than steel, their longevity and low maintenance requirements may justify the investment.

Copper is another premium choice known for its aesthetic appeal and impressive durability. It develops a distinctive patina over time, adding character to a home. However, the high cost of copper roofing often limits its use to high-end residential properties or commercial buildings. Lastly, zinc combines the positives of both aluminum and copper, offering excellent corrosion resistance and low maintenance. It is widely appreciated for its sustainability and is often chosen by environmentally conscious homeowners.

When selecting the right metal roofing material, various factors come into play, including local climate, budget constraints, and personal preferences regarding appearance. It is essential to weigh these considerations carefully, as the right material can significantly enhance the longevity and efficiency of your roofing system. In this way, the choice of metal roofing material is not merely a matter of preference but should reflect both practical and aesthetic needs. Each material brings unique properties, ensuring that a suitable option exists for every homeowner’s requirements.

Safety Precautions During Installation

When undertaking a metal roofing installation project, prioritizing safety is paramount to ensure the well-being of all individuals involved. Proper preparation and adherence to safety protocols can significantly reduce the risk of accidents and injuries. One of the first steps is to equip workers with appropriate personal protective equipment (PPE). This includes safety helmets, gloves, non-slip footwear, and eye protection to safeguard against potential hazards associated with metal roofing materials.

Another critical aspect of safety during the installation process is ladder safety. Ladders should be inspected prior to use to ensure they are in good condition, and the appropriate ladder type must be utilized based on the height of the roof. It is essential to position ladders on stable, level ground and maintain three points of contact at all times while ascending or descending. Moreover, it is advisable to have a fellow worker present to assist and observe during ladder maneuvers, as this can help identify any potential risks, particularly in adverse weather conditions.

Furthermore, handling tools responsibly is a crucial component of ensuring safety during metal roofing installation. Workers should familiarize themselves with tools before use and adhere to the manufacturer’s instructions. Keeping the work area tidy can help prevent slips and trips caused by misplaced materials or tools. Awareness of the surroundings is also vital; installers must be vigilant about overhead power lines, slippery surfaces, and changes in weather that may elevate the risk of accidents.

Lastly, conducting regular safety briefings with the installation team can serve as an effective way to highlight potential hazards and review safety measures. Identifying and assessing various risks during metal roofing installation helps to foster a culture of safety, ultimately ensuring a successful and incident-free project. Implementing these essential tips for metal roofing installation will ensure not only the efficiency of the task but also contribute to the overall safety of the workers involved.

Installation Techniques and Best Practices

Understanding the installation techniques for metal roofing is crucial for achieving longevity and performance. One of the primary considerations is the choice between fasteners versus clips. Fasteners are commonly used to secure metal panels directly to the underlying structure, providing a secure attachment. However, this method can lead to potential water infiltration if not sealed correctly. Alternatively, clips allow for thermal expansion and contraction, enabling the metal panels to move without compromising the integrity of the roofing system. It is advisable to consult manufacturer guidelines to determine the best option for your specific roofing situation.

Proper insulation is another essential aspect of metal roofing installation. Insulation not only enhances energy efficiency but also protects against condensation, which can lead to premature deterioration of the roofing materials. When installing metal roofs, it is important to choose the right type of insulation, ensuring that it meets local building codes and performance expectations. This attention to detail helps in maintaining comfortable indoor temperatures and prolonging the life of your roof.

Furthermore, ensuring proper alignment and spacing during installation is critical. Panels should be laid in a manner that allows for adequate overlap, minimizing the risk of leaks. Moreover, spacing between panels should be consistent, which aids in visual appeal and structural soundness. It is also vital to check the manufacturer’s specifications regarding the recommended distance for fastening and the maximum lengths of panels to be used without intermediate support.

When it comes to sealing joints, proper techniques must be employed to prevent water penetration. It is advisable to use high-quality sealants and gaskets specifically designed for metal roofing. Ensuring that all seams and joints are properly sealed contributes significantly to the durability and performance of the roofing system.

Flashing and Waterproofing Considerations

One of the key components in ensuring a successful and durable metal roofing installation is the proper application of flashing. Flashing acts as a protective barrier, preventing water from infiltrating the vulnerable areas such as vents, chimneys, and roof edges. To maximize the lifespan of your metal roof, it is essential to carefully plan and install flashing where needed. For instance, when installing flashing around a chimney, it’s crucial to use materials that match the metal roofing for a uniform appearance, while ensuring that all seams and joints are well-sealed to eliminate any potential leak points.

For vent installations, flashing should be installed in a way that directs water away from the transition areas between the roof and the vent. This may involve constructing a custom flashing piece that fits snugly around the base of the vent, ensuring that it overlaps adequately with the roofing panels. Utilizing high-quality sealants during the installation process will further enhance the waterproofing features and provide additional protection against moisture intrusion.

Additionally, waterproofing plays a critical role in the overall integrity of metal roofing systems. Implementing appropriate waterproofing techniques is vital to prevent leaks and subsequent damage. For example, one might consider using peel-and-stick membrane products that provide an extra layer of protection on particularly vulnerable areas of the roof, such as valleys and eaves. Ensuring that all roofing materials are properly layered and that overlaps are strategically planned will contribute significantly to the roof’s waterproof capabilities.

By focusing on the proper installation of flashing and incorporating robust waterproofing measures, homeowners can protect their investment in metal roofing systems and enhance the longevity and performance of their roof. These essential tips for metal roofing installation are critical for achieving optimal results and minimizing maintenance requirements in the future.

Maintenance Tips for Metal Roofing

Proper maintenance is fundamental for maximizing the lifespan and performance of a metal roof. To ensure your roofing system remains durable and effective over time, it is recommended to perform regular inspections at least twice a year. During these inspections, be sure to look for loose seams, missing fasteners, and any signs of rust or corrosion. Early identification of issues can significantly reduce the need for extensive repairs in the future.

Another essential task is cleaning the gutters and downspouts. Clogged drainage systems can lead to water accumulation, potentially causing damage to both the roof and the underlying structure. Make it a priority to remove debris, such as leaves and dirt, to maintain proper water flow. It is advisable to perform this maintenance in the spring and fall when debris is more likely to accumulate.

After severe weather events, such as storms or heavy snowfall, conduct a thorough inspection. Check for any visible damage, such as dents or bends, particularly in areas susceptible to strong winds. Pay close attention to the roof’s edges, where wind can create the highest pressure, leading to potential weaknesses.

Prolonging the life of your metal roofing involves routine maintenance practices, which include applying a protective coating periodically. This not only enhances the roof’s aesthetic appeal but also provides an added layer of protection against rust and UV rays. Additionally, ensure any overhanging branches are trimmed back to prevent potential scratching or puncturing of the roof surface.

Incorporating these maintenance tasks into your routine ensures that your metal roof remains functional and extends its longevity. By investing time and effort into these essential maintenance tips for metal roofing installation, you contribute to the overall durability of the system and reduce long-term costs associated with repairs and replacements.

Common Mistakes to Avoid

When it comes to metal roofing installation, avoiding common mistakes can significantly enhance the outcome of the project. One of the most prevalent errors made by both DIYers and professionals is improper fastening. Metal roofing panels require secure fastening to resist wind uplift and to ensure the longevity of the roof. Inadequate fastening not only increases the risk of panels coming loose but also creates opportunities for water infiltration, which can lead to structural damage over time.

Another mistake often observed during installation is neglecting the installation of flashing. Flashing is crucial as it directs water away from seams and penetrations, thereby preventing leaks. Skipping or improperly installing flashing around chimneys, vents, and other roof projections can create vulnerabilities, making your roof more susceptible to water damage. When planning for metal roofing installation, it is vital to prioritize flashing around these critical areas to safeguard against potential leaks.

Additionally, ventilation is a critical aspect that should not be overlooked. Failing to account for adequate ventilation in a metal roofing system can result in heat buildup in the attic, leading to increased energy costs and potential damage to roofing materials. Proper airflow helps to reduce moisture accumulation, which can contribute to mold growth and compromise the integrity of the roof. It is essential to ensure that ventilation methods, such as ridge vents or soffit vents, are adequately incorporated into the design of the installation.

Being aware of these common mistakes is fundamental to a successful installation process. By addressing improper fastening methods, ensuring correct flashing installation, and considering ventilation, homeowners can avoid unnecessary repairs and expenses, ultimately achieving a durable and efficient metal roof.

Conclusion and Final Thoughts

In the realm of roofing, metal has emerged as a favored option due to its durability, energy efficiency, and aesthetic appeal. The essential tips for metal roofing installation highlighted throughout this article serve as a comprehensive guide for homeowners and contractors alike. Careful planning and execution are pivotal to reaping the full benefits of this roofing material.

Firstly, selecting the right type of metal—whether it’s steel, aluminum, or copper—ensures compatibility with local environmental conditions and aesthetic preferences. Optimal installation involves pre-planning, which includes assessing the structure’s load-bearing capabilities and ensuring proper underlayment to mitigate moisture issues. Proper spacing and fastening techniques are also crucial, as they enhance the integrity and lifespan of the roofing system.

Furthermore, attention to maintenance cannot be overstated. Regular inspections and prompt addressing of any issues, such as rust or loose seams, will extend the lifespan of metal roofing significantly. These proactive steps ensure that the initial investment yields optimal long-term returns, both in performance and curb appeal.

The benefits of choosing metal roofing are numerous, including lower heating and cooling costs, resistance to adverse weather conditions, and minimal maintenance requirements. With the integration of the essential tips for metal roofing installation discussed here, homeowners can embark on their roofing projects with confidence.

Ultimately, successful metal roofing installation is a combination of careful choice of materials, diligent planning, and ongoing maintenance. By adhering to these guidelines, individuals can not only enhance the durability of their roofs but also elevate their property’s overall value and aesthetic. Taking actionable steps today can pave the way for a resilient and attractive roofing solution tomorrow.