Asphalt shingle roofing has emerged as one of the most popular and widely used roofing materials in residential construction across North America. This popularity can be attributed to several key attributes, including cost-effectiveness, durability, and aesthetic versatility. Homeowners often opt for asphalt shingles due to their ability to provide excellent protection against various weather conditions while being available at competitive prices. This makes them an attractive option for new constructions as well as roofing replacements.

One of the primary benefits of asphalt shingles is their durability. When installed correctly, they can withstand harsh weather climates, including high winds, rain, and even snow. Furthermore, many asphalt shingles come with lengthy warranties, offering homeowners peace of mind regarding their durability and longevity. This resilience contributes to lower long-term maintenance costs, reinforcing the overall value proposition of installing an asphalt shingle roofing system.

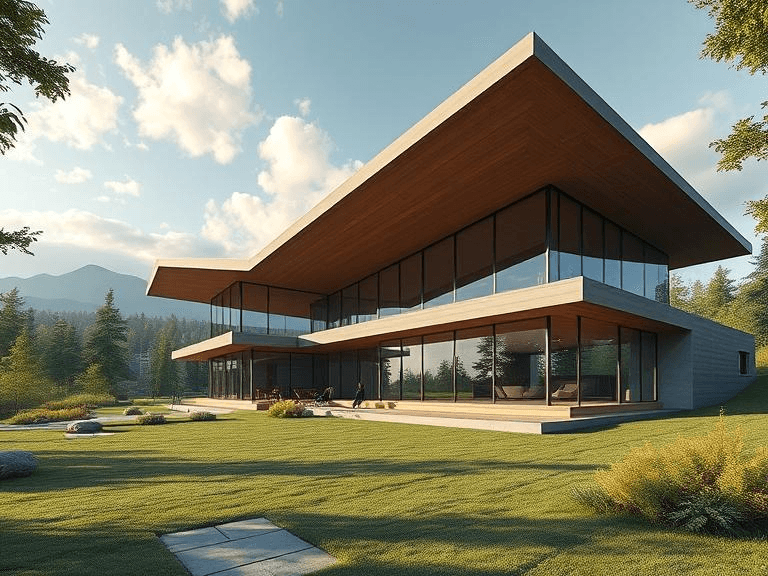

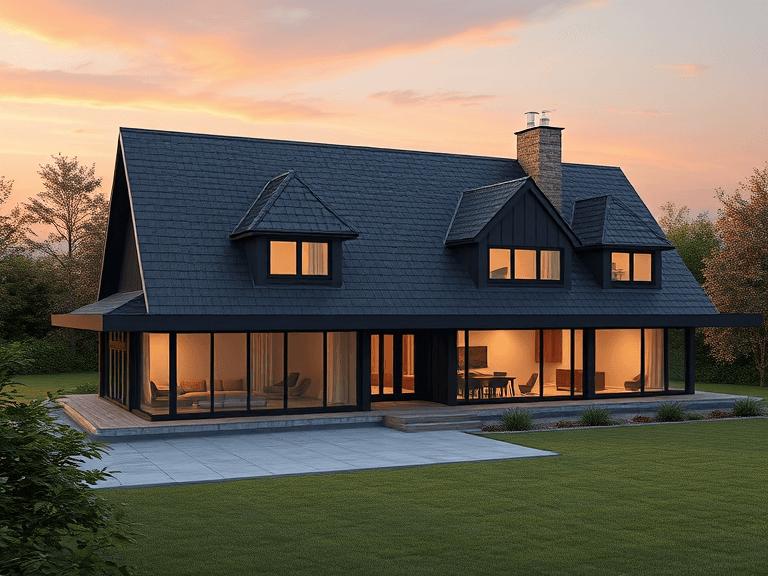

In addition to practicality, asphalt shingles provide a wide range of aesthetic options. They are available in various styles, colors, and designs, allowing homeowners to select a roof that complements their home’s architectural style. Whether one prefers traditional, contemporary, or unique designs, asphalt shingles can cater to diverse tastes, enhancing the overall curb appeal of the property.

When considering the installation of an asphalt shingle roofing system, several factors come into play. Different types of asphalt shingles, such as architectural, three-tab, and premium options, present various benefits and price points. Additionally, the choice of colors can significantly impact the home’s aesthetic. Understanding these variables is essential for making informed decisions and ensuring the selected roofing system meets both functional and visual requirements.

Tools and Materials Needed

When embarking on the process of installing an asphalt shingle roofing system, it is crucial to gather the right tools and materials to ensure a successful installation. The selection of high-quality products will not only enhance the durability of the roof but also contribute to the overall efficiency of the installation process.

First and foremost, safety gear must be considered. Proper safety equipment including hard hats, safety goggles, work gloves, and slip-resistant footwear is essential to protect the worker while performing tasks at elevated heights. Additionally, a reliable harness system should be utilized to adhere to safety protocols during the roofing process.

Next, the primary materials required for installing asphalt shingles include the shingles themselves, roofing underlayment, and fasteners. Asphalt shingles come in various styles and colors; hence, selecting high-quality shingles that align with both aesthetic preferences and climate conditions is vital. Roofing underlayment acts as an additional layer of protection; it provides a barrier against water and ice, thereby prolonging the life of the roofing materials. Fasteners, typically roofing nails or staples, must be chosen based on the manufacturer’s specifications to ensure a secure attachment.

Accessories such as flashing and ventilation components are also key to a well-installed asphalt shingle roof. Flashing is critical for preventing leaks around chimneys, vents, and other roof penetrations. Ventilation systems work to maintain optimal airflow, reducing the chance of moisture accumulation and improving the longevity of the roofing components.

In summary, the successful installation of an asphalt shingle roofing process hinges on having the right tools and materials at hand. By investing in quality products and adhering to proper safety measures, the process can be conducted smoothly and efficiently, ensuring a durable and long-lasting roof.

Preparing the Roof Deck

Preparing the roof deck is a crucial step in the installing an asphalt shingle roofing process, as it sets the foundation for a durable and effective roof system. The first step involves conducting a thorough inspection of the existing roof structure. It is vital to identify any signs of damage or deterioration, such as rot, mold, or weakened boards. Addressing these issues promptly helps to ensure all components are structurally sound, ultimately enhancing the longevity of the new roof.

Once any damage is located, it is necessary to replace or repair these compromised sections of the roof deck. This may involve removing old shingles or roofing material to expose the underlying structure, followed by replacing any boards that have succumbed to rot or water damage. Utilizing high-quality materials during this process helps prevent future issues that could arise from rain or snow infiltration.

In addition to replacing damaged boards, cleaning the surface is imperative. Removing debris, dirt, and any remaining roofing materials will create a clean workspace for the installation of asphalt shingles. A clean deck allows for better adherence of roofing materials and minimizes the risk of embedding debris that could result in future leaks.

Furthermore, ensuring proper slope and drainage is essential for any roof installation. The roof deck should be sloped adequately to facilitate water runoff, reducing the risk of standing water that could lead to leaks or structural damage. This entails assessing the current angle of the roof and making necessary adjustments to achieve optimal drainage conditions.

Overall, adequately preparing the roof deck not only sets the stage for a successful installation of asphalt shingle roofing but also plays an integral role in the roof’s long-term performance. Taking these steps seriously will help to avoid common pitfalls that can lead to complications later on.

Installing Underlayment

The underlayment serves as a critical component in the asphalt shingle roofing process, providing a barrier against moisture and enhancing the overall durability of the roof. It is essential to select the appropriate type of underlayment to match the specific needs of your roofing project. The two primary types of underlayment are felt and synthetic. Felt underlayment, made from either asphalt-saturated paper or fiberglass, is a traditional option that has been utilized for many years. It is reasonably economical and effective, although it may have limitations in areas prone to significant moisture. On the other hand, synthetic underlayment offers superior durability and moisture resistance, making it increasingly popular among roofing professionals.

When installing underlayment, proper techniques are vital to ensure a resilient roofing system. Begin by ensuring that the roof deck is clean and dry to facilitate strong adhesion. For felt underlayment, roll it out starting at the eave, overlapping each subsequent row by at least two inches. Utilize roofing nails to secure the felt, placing them along the upper edge while avoiding any raised edges that could lead to water infiltration. If opting for synthetic underlayment, the installation process is similar; however, the use of adhesive technology is recommended for enhanced performance in high-wind areas.

Regardless of the underlayment selected, it is crucial to ensure proper overlap and sealing at both tips and seams. Overlapping different layers will help direct water away from the roof structure, while sealing joints with appropriate adhesives or roofing tape facilitates enhanced moisture protection. Paying close attention to these details during the installation will contribute significantly to the longevity and effectiveness of the asphalt shingle roofing process, safeguarding the home against wind and water damage over the years.

Laying the Asphalt Shingles

The process of laying asphalt shingles begins at the eave of the roof, which is the lowest edge. It is crucial to ensure that the roof deck is clean, dry, and free from any debris before starting the installation. Begin by placing a starter strip along the eave, which serves as the foundation for the first row of shingles and helps to prevent wind uplift. The starter strip should overhang the eave by approximately half an inch, providing added protection against water infiltration.

Next, the first row of asphalt shingles is installed. Align the shingles so they are straight and level, ensuring they extend slightly beyond the starter strip. In order to achieve a sturdy installation, fasten each shingle with nails placed in the marked nailing line, which is approximately 5-6 inches from the bottom edge. It is important to use the proper type and number of roofing nails for optimal performance.

As you continue to install the successive rows of shingles, it is essential to stagger the seams. This method not only enhances the aesthetic appearance of the roof but also contributes to its waterproof nature. A standard staggered pattern involves offsetting each row by at least half the width of the shingles. Ensure to maintain proper alignment throughout this process, which will prevent any gaps or misalignments that could lead to water penetration.

After placing several rows, consider the importance of securing the shingles with nails in the appropriate positions; typically, four to six nails per shingle is recommended, depending on local building codes. Each nail should penetrate through the shingle and into the roof deck adequately. By consistently following these procedures, you will create a robust, weather-tight installation, ensuring the longevity and effectiveness of the asphalt shingle roofing process.

Flashing and Ventilation Installation

The installation of flashing is a crucial step in the asphalt shingle roofing process. Flashing serves as a protective barrier in areas susceptible to water intrusion, such as valleys, chimneys, and around skylights. When rainwater flows down the roof, it may gather around these critical joints or protrusions, creating a risk of leakage. Therefore, it is vital to use high-quality flashing material, typically made of metal, to redirect water away from these vulnerable areas.

In valleys, the method of installing flashing usually involves cutting the shingles back to ensure that the metal is secured in position beneath. Overlapping the flashing at least six inches across the valley minimizes water pooling, thus preventing potential leaks. For chimneys and skylights, flashing should be installed in a step method, utilizing counter-flashing that hangs over the top edges of the structures. This technique effectively channels water away and protects your roofing system from intrusion.

While flashing protects the integrity of the roof, adequate ventilation is equally important in the asphalt shingle roofing process. Proper ventilation helps in regulating airflow within the attic space, reducing heat buildup and preventing moisture accumulation. This is essential as excessive heat can lead to shingle deterioration while trapped moisture can contribute to mold growth and wood rot.

Various ventilation methods can be employed, such as passive vents, ridge vents, or gable vents. During installation, ensure that the attic has a balanced intake and exhaust system, allowing for efficient airflow. The correct ratio of intake to exhaust openings is vital; a general guideline is to have one square foot of ventilation for every 300 square feet of attic space. Overall, careful attention to flashing installation and ventilation ensures a long-lasting and effective asphalt shingle roofing system.

Cutting and Finishing Touches

When undertaking the process of installing an asphalt shingle roofing system, precise cutting techniques are essential for achieving a neat and professional appearance. The edges of the shingles should be carefully tailored to fit around obstacles such as chimneys, vents, and roof ridges. A common method for cutting shingles is utilizing a utility knife. This tool allows for clean, straight cuts, which are necessary for maintaining the integrity of the roofing layers. For intricate cuts around vents or unique rooftop features, tin snips or a specialized roofing cutter can provide added control and precision.

Moreover, when it comes to the edges of the roof, a technique known as “shingle layering” can be employed. This ensures that overhangs are evenly distributed, which not only enhances the roof’s aesthetic appeal but also serves a functional purpose by directing water runoff away from the house’s foundation. It is critical to measure and mark the shingles before making any cuts to avoid waste and ensure a consistent look throughout the installation process.

After the main shingles are installed, attention must shift to the ridge caps, which are essential for protecting the ridge line of the roof from wind and rain. The ridge caps, typically made from similar asphalt materials, are crafted to fit snugly over the peak of the roof. Installing these caps requires carefully aligned cuts that mirror the slope of the roof to achieve proper ventilation and drainage. Adequate sealing under the ridge caps will prevent water ingress and improve the durability of the roofing system. Additionally, finishing touches such as edge trim can also be incorporated to enhance the overall visual appeal and functionality of the roof.

Post-Installation Inspection

After successfully completing the installation of asphalt shingle roofing, it is crucial to conduct a thorough post-installation inspection to ensure the roofing system performs as intended. This inspection serves to confirm that all aspects of the installation meet the required standards and specifications, safeguarding against potential issues down the line. The first step in this inspection process involves checking the alignment of the shingles. Proper alignment not only affects the aesthetic appeal of the roof but also plays a significant role in preventing water infiltration. Any misaligned shingles should be promptly adjusted to maintain both functionality and appearance.

Next, the inspection should focus on ensuring that the shingles are properly sealed. The sealing process is vital as it prevents wind uplift and enhances the roof’s weather resistance. Check for any areas where the adhesive may not have fully set or where shingles appear to be lifting. Using a heat gun or a roofing torch, one may rekindle the adhesive in unbonded sections, ensuring a secure fit. Additionally, it is recommended to inspect the effectiveness of the flashing installed at roof penetrations and valleys. Properly installed flashing should create a watertight barrier and divert water away from critical areas.

Common mistakes to look out for during the post-installation inspection include overlooked nail placements and insufficient overlap between shingles. Ensure that nails are placed in proper positions—not too high or low—to avoid compromising the shingles’ envelope. Furthermore, make sure that each row of shingles overlaps the previous one adequately. Attention to these details during the inspection provides reassurance that the installing an asphalt shingle roofing process has been completed correctly, significantly extending the roof’s lifespan and performance.

Maintenance Tips for Longevity

Proper maintenance is crucial for extending the lifespan of asphalt shingle roofing. Regular inspections are a proactive approach that homeowners should adopt. It is advisable to conduct these inspections at least twice a year—preferably in spring and fall. Look for signs of damage, such as missing or curling shingles, which can indicate underlying problems that may need immediate attention. Furthermore, inspecting flashing around chimneys and vents is essential as these areas are prone to leaks if not properly maintained.

Another significant aspect of maintenance involves gutter cleaning. Clogged gutters can lead to water pooling on the roofing surface, increasing the risk of leaks and damage to the shingles. It is recommended that homeowners clear debris from gutters regularly, ideally following heavy storms or strong winds. This practice ensures that water flows freely from the roof, reducing the chances of water-related issues that may arise from improper drainage.

Addressing minor repairs promptly is another critical maintenance tip. Small issues, such as loose shingles or minor leaks, if left unattended, can escalate into larger, more expensive problems. Homeowners should not hesitate to replace damaged shingles or seal minor leaks as soon as they are discovered. Furthermore, applying a roof sealant, as needed, can offer additional protection against the elements and enhance the durability of the shingles.

Additionally, keeping surrounding tree branches trimmed back is beneficial. Overhanging branches can scratch or damage the surface of the shingles, and they can also contribute to debris accumulation in gutters. By maintaining a clear zone around the roof, homeowners can minimize the risk of sustained damage over time. A consistent maintenance routine that includes these practices will significantly contribute to the longevity of an asphalt shingle roofing system.